New possibilities with forwarding

We look beyond our own loading units and exploit the full potential of the network. This includes both road and intermodal transport. Curious about the possibilities?

Based on the specifications, geography and your preferences, we select several transport solutions for your liquid and dry bulk products. Intermodal or road transport? Carried out with our own loading units or using the capacity of the network? The choice is yours. We also make the potential CO2 savings transparent on our proposal, because bulk transport can not only be more efficient, but greener too.

Get to know Bulkio

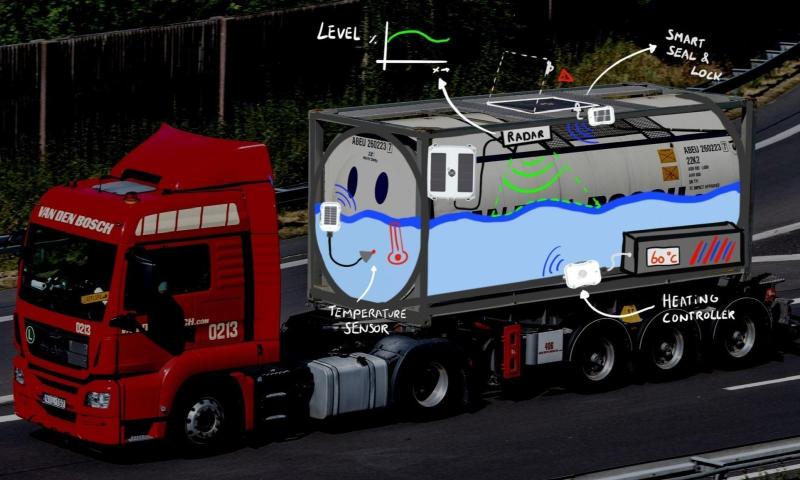

Bulkio is the driving force behind our forwarding solutions. Developed within Van den Bosch, this online matching platform brings together supply and demand in the market. Over 1,500 carriers have already joined Bulkio, and the platform continues to grow. We use the latest technologies to digitally connect our partners. In doing so, we are continuously reducing empty kilometres and making transport more sustainable.

These partners are not just carriers. We work with local specialists who know their trade. Quality and safety is our top priority. Through access requirements, performance management and assessments, we work continuously on quality assurance to ensure that your goods are always in good hands.